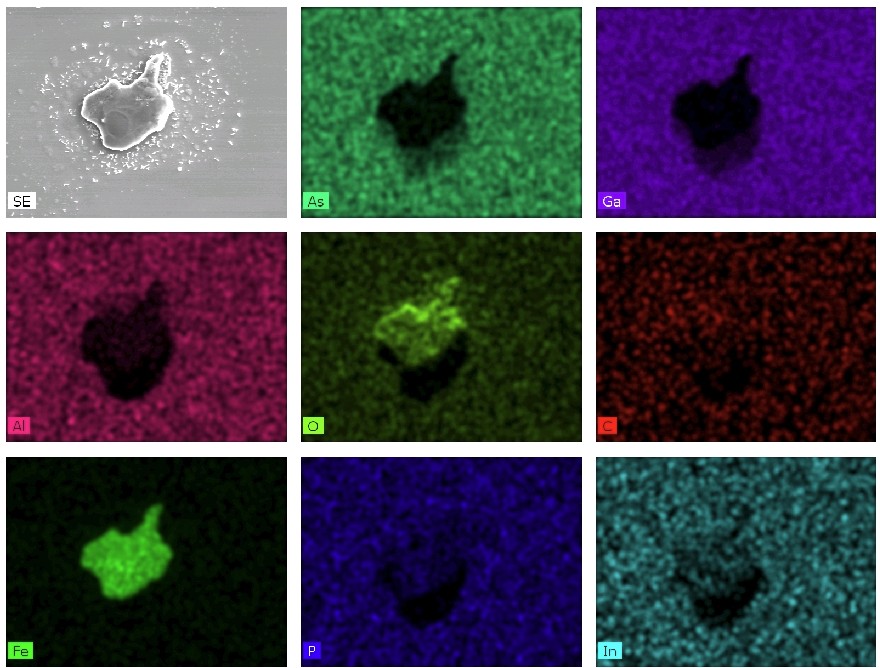

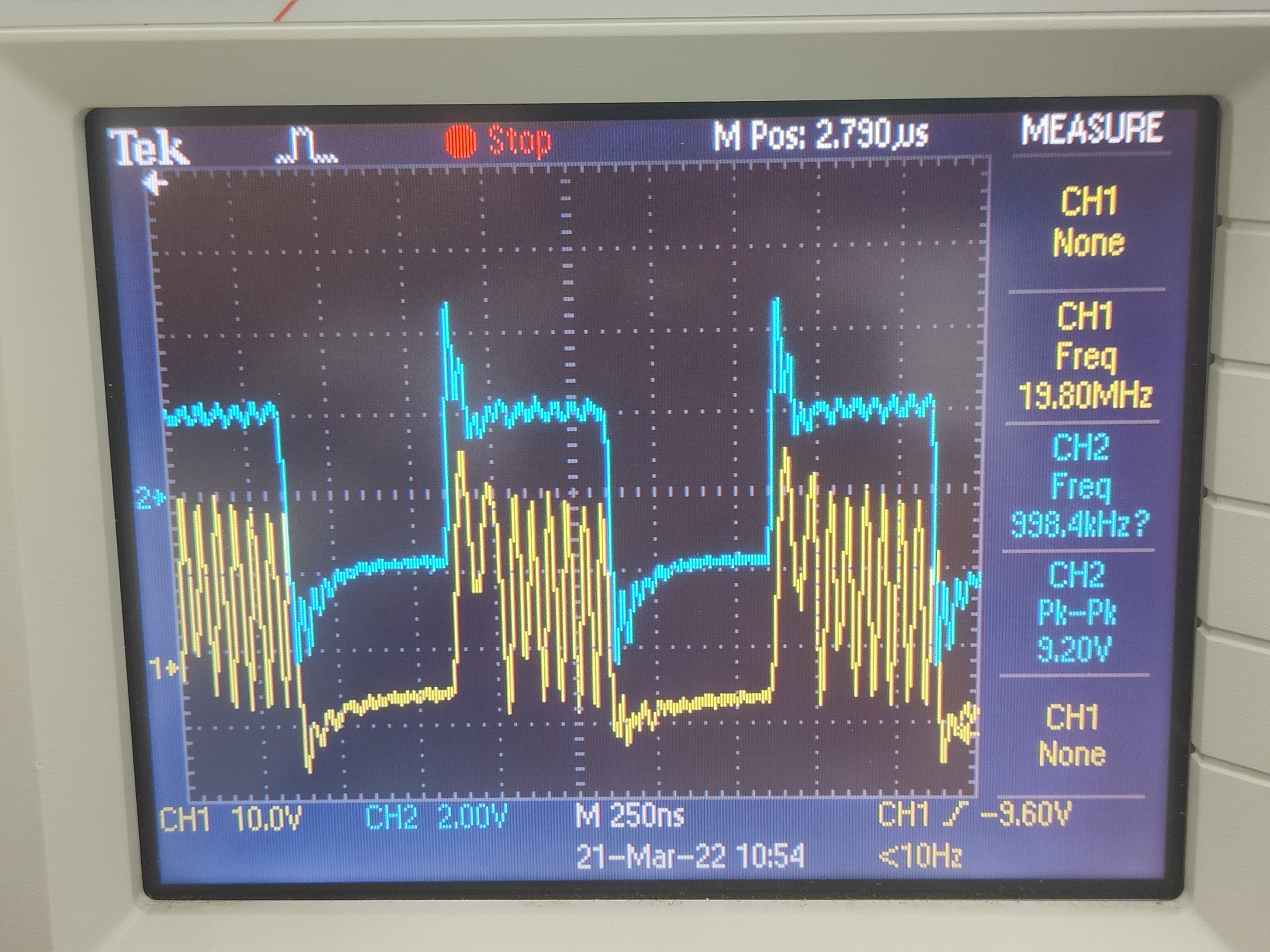

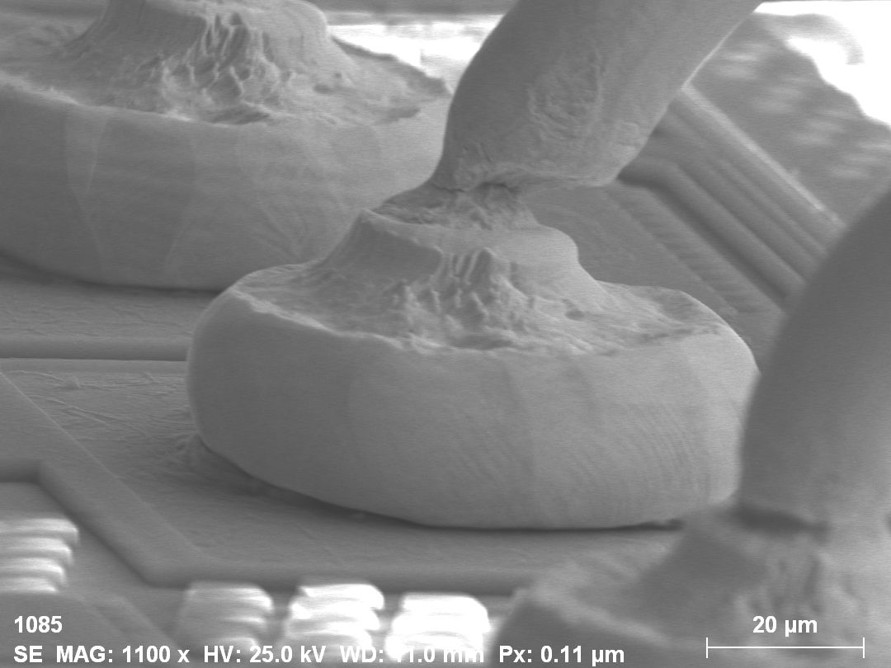

Inscope Labs is a state‑of‑the‑art laboratory providing comprehensive, one‑stop solutions in cutting‑edge testing, failure analysis, device validation, and materials characterization. Headquartered in Singapore and serving clients worldwide, we partner with leading organizations across a diverse range of industries.

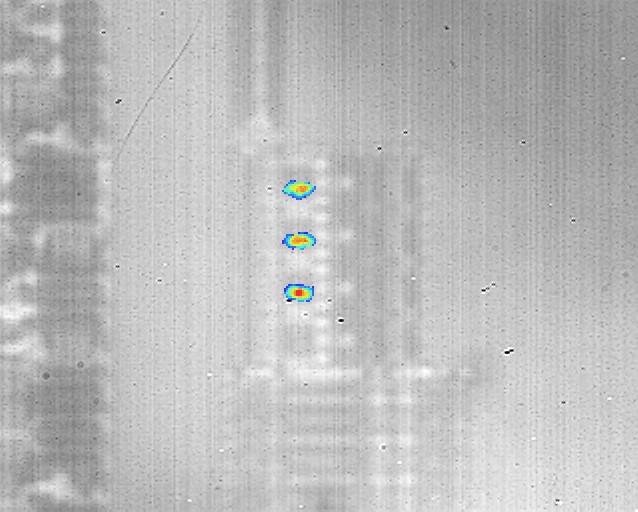

As a full‑service analytical partner, we offer everything from hourly SEM services to the most advanced optical probing techniques, right through to full virtual lab partnerships with multinational enterprises. Our combination of analytical capabilities and deep scientific expertise enables clients to accelerate innovation, enhance performance, and maintain a decisive competitive edge. A wholly‑owned subsidiary of SEMICAPS — a global leader in high‑resolution infrared laser scanning microscopes — Inscope Labs leverages world‑class technology and know‑how to deliver unmatched quality, insight, and speed.